The Evolution of Book Printing: A Deep Dive into Embossing and Debossing Technology

In the world of book printing, the artistry of design is as vital as the words within. Among the various printing techniques, embossing and debossing in book printing stand out for their ability to transform a book cover into a tactile and visual masterpiece. These technologies offer a unique way to enhance the aesthetics and feel of books, making them irresistible to touch and behold. Let’s explore how these methods work, their advantages, and the technological advancements shaping their future.

What is Embossing and Debossing?

Both embossing and debossing in book printing are print-finishing techniques that add dimension to the design of a book cover. While they are often used interchangeably, they have distinct processes and effects.

- Embossing: This technique raises a design on the surface of the material, creating a three-dimensional effect. Embossed elements are typically used to highlight specific areas such as titles, logos, or intricate designs.

- Debossing: In contrast, debossing creates an indentation, pressing the design into the surface of the material. It gives a subtle, elegant effect, often used for understated yet sophisticated designs.

The Technology Behind Embossing and Debossing

1. The Process

Both embossing and debossing rely on metal dies and pressure:

- Design Creation: The design is etched or engraved onto a metal die, which serves as a mold.

- Heat and Pressure: The material (often paper, leather, or cloth) is placed between the die and a counter-die. Heat and pressure are applied to transfer the design.

- Customization: The process can include color foiling or blind embossing/debossing (no added color), depending on the desired effect.

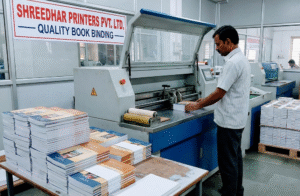

2. Modern Machinery

With advancements in printing technology, modern embossing and debossing machines are faster, more precise, and versatile:

- CNC Machining for Dies: Computer Numerical Control (CNC) machines ensure highly accurate die engraving.

- Digital Die Manufacturing: Reduces the time and cost of creating custom dies.

- Automatic Feeders: Allow for mass production without compromising quality.

- Laser Engraving: Adds intricate detail and precision, ideal for complex designs.

Applications in Book Printing

- Luxury Editions: High-end books, such as collectors’ editions, often use embossing and debossing to add a touch of luxury.

- Branding: Publishers use these techniques to reinforce brand identity with distinct logos and typography.

- Customization: Limited editions and personalized books leverage embossing/debossing for uniqueness.

- Illustrative Covers: Artistic designs can come alive with the dimensional quality of embossing or debossing.

Advantages of Embossing and Debossing

- Aesthetic Appeal: Adds depth and sophistication to the design.

- Tactile Experience: Enhances the sensory appeal of holding a book.

- Versatility: Works on a variety of materials and complements other printing techniques like foil stamping.

- Durability: The design becomes part of the material, making it long-lasting.

Challenges and Solutions

1. Cost

The creation of custom dies can be expensive, particularly for small print runs.

Solution: Digital die-cutting and reusable dies for similar designs help reduce costs.

2. Time-Intensive Process

The setup and production can be time-consuming.

Solution: Automated machinery and streamlined workflows are addressing these delays.

3. Material Limitations

Some materials may not respond well to the pressure or heat required.

Solution: Advances in material science and adaptive machinery are expanding the range of suitable substrates.

The Future of Embossing and Debossing

The future of embossing and debossing lies in further integration with digital technologies:

- AI-Powered Design Tools: Allow for intricate patterns and personalized designs at scale.

- Sustainability: Eco-friendly materials and processes will dominate, driven by demand for greener publishing practices.

- Hybrid Techniques: Combining embossing/debossing with augmented reality (AR) and QR code integration on book covers.

- On-Demand Printing: Innovations in die-free digital embossing systems for rapid customization.